PRODUCTION

PRODUCTION

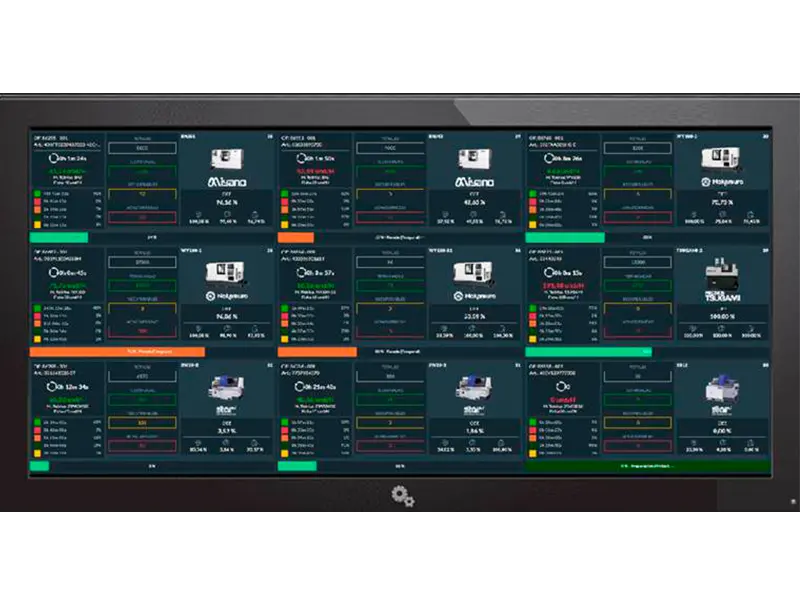

PRODUCTION MANAGEMENT DIGITAL TOOL

As we have evolved, we have always opted for specialisation in machining small and medium batches (from 50 to 10,000 parts), covering an increasingly wide and complex range of parts, which has led us to stand out for our flexibility and production capacity. Digitalisation involves taking another qualitative leap, allowing us to optimise our processes and maximise our competitive edge.

This new comprehensive platform is a tool that allows our management team, production supervisors and operators to view the status of each lathe in real time. This provides a very valuable flow of information to be able to simply and effectively make decisions. There is also a dynamic planner which allows us to drastically improve and speed up the arduous task of production planning.

RAW MATERIAL WAREHOUSE

- CARBON, NITRIDING, CEMENTATION STEEL…

- EASY-MACHINING STEELS (11SMnPB)

- STAINLESS STEELS (AUSTENITIC, MARTENSITIC, MAGNETIC)

- BRASS

- COPPER

- BRONZES

- ENGINEERING PLASTICS

- ALUMINIUMS

- TITANIUM, DUPLEX,

- SUPERDUPLEX, INCONELS

We work using round bars, hexagonal bars, tubes, platens and billets.

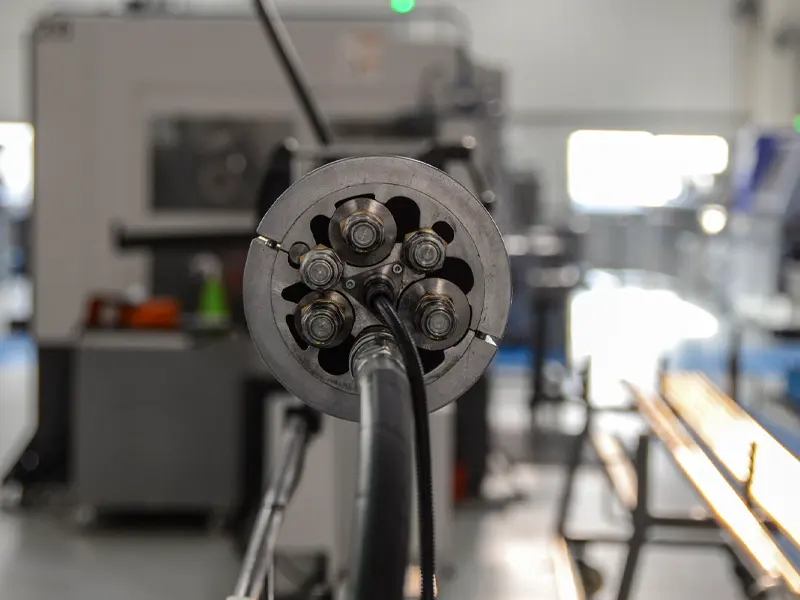

CNC LATHES

Fixed Head

We have 10 CNC lathes with a fixed head and motorised tool.

Up to maximum bar capacity of Ø64mm, with 11 controlled axes, 24 tools and the possibility of simultaneously performing multiple operations on the same spindle.

Possibility of working with a claw ring for larger-sized parts, with a max. Ø of 200mm.

Mobile Head

Up to maximum bar capacity of Ø64mm, with 11 controlled axes, 24 tools and the possibility of simultaneously performing multiple operations on the same spindle.

Possibility of working with a claw ring for larger-sized parts, with a max. Ø of 200mm.

SMART TOOL STORE

ASSEMBLY AND SECOND OPERATIONS

WASHING MACHINE

QUALITY

As a company specialised in made-to-measure manufacturing of elements intended for very demanding environments, the Quality area plays a key role in our production process and is responsible for thoroughly checking the requirements of each order.

In our quest for continuous improvement, we have boosted our Quality department by creating a specific metrology room with new machinery and by expanding the team dedicated to quality control of our processes.

We maintain our commitment to quality, the environment and efficient management in the manufacturing processes of our products. We are committed to health and safety in the work environment.

We hold the following certificates: ISO9001 (Quality Management), ISO14001 (Environment) and ISO45001(Workplace Health and Safety), accredited by ENAC. ISO9001, 14001, 45001

Control Methods

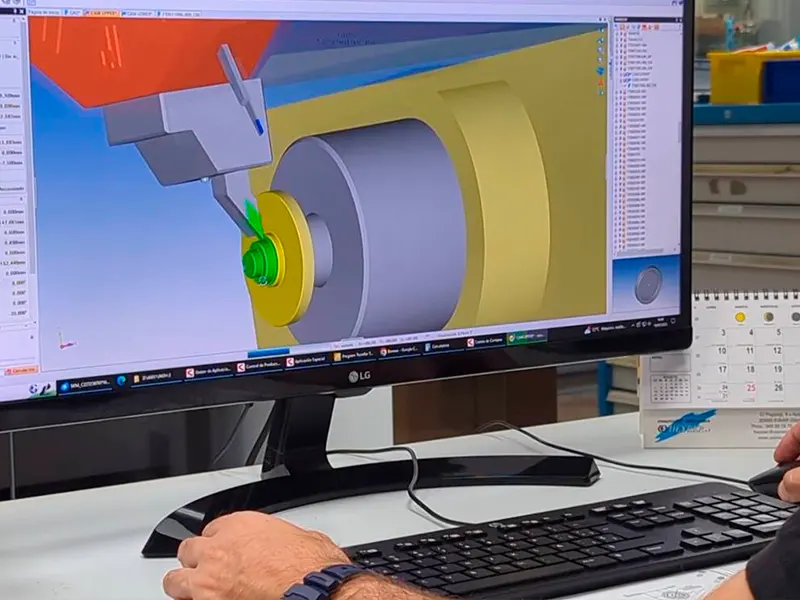

CAD CAM

Computer-aided design allows us to create, modify, analyse and document 3D graphic representations.

This gives us the possibility of carrying out CNC programmes that are extremely geometrically complex.